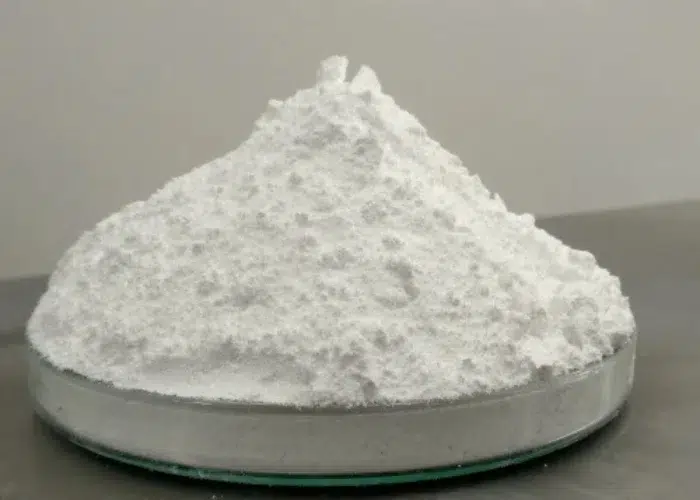

High-Performance Sieving & Blending Solutions for PVC Resin Powder Processing

PVC resin powders—used in pipes, profiles, cables, flooring, and films—require precise particle sizing and homogeneous blending for smooth processing and product quality. However, these powders are prone to clumping, electrostatic buildup, and inconsistent dispersion, especially when mixed with plasticizers, stabilizers, or colorants.

A polymer processing company partnered with JS Vibro to improve the efficiency and consistency of their PVC compound preparation, solving key issues like agglomeration, uneven additive distribution, and poor material flow.

Purpose-Built Systems for PVC Resin Powder Applications

Vibro Sifter was used to screen out lumps, oversized particles, and contaminants from PVC base resin, ensuring smooth flow into high-speed mixers or extruders—reducing blockages and improving melt consistency.

Ribbon Blender provided uniform dry mixing of PVC resin with fillers (like calcium carbonate), lubricants, stabilizers, and color masterbatches—delivering reliable dispersion before granulation or compounding.

Distinct Advantages of JS Vibro for PVC Resin Handling:

- Anti-Static Design Options: Minimizes powder clinging and dust buildup

- Heavy-Duty Construction: Withstands abrasive fillers like CaCO₃ and TiO₂

- Fine Particle Sieving (Up to 300 mesh): Prevents agglomerates in extrusion feed

- Uniform Additive Distribution: Enhances mechanical and thermal stability

- Quick Clean Design: Ideal for shifting between different PVC grades or colors

Perfect For:

- Rigid and flexible PVC compounding

- Cable insulation and conduit manufacturing

- PVC pipe, profile, and sheet extrusion

- Flooring and decorative film production

- Plasticizer and color masterbatch blending