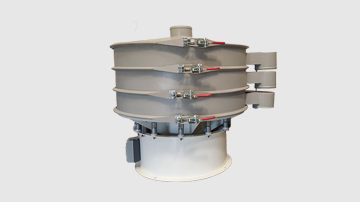

Oil Industry Vibro

When seeds is expelled for oil extraction CCO contains huge amount of solid which is to be removed by downstream. Conventionally settling, neutralization and decantation process is applied. Settling needs long time to separate large material. Steam consumption in neutralization adds cost to product. In case solid going to decanter increased it leads to chocking and failure of bearing. Maintenance of decanter is too much as it is very high speed rotating equipment.

Fesutures and Benefits

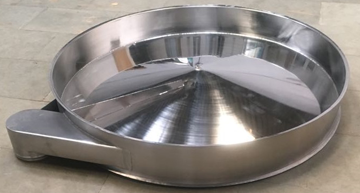

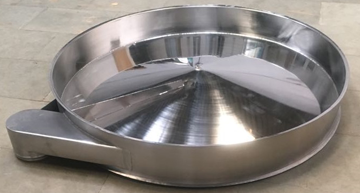

- Gentle material handling

- Robust construction

- Automatic material discharge

- Less vibration

- Easy and quick change of screen mesh

- Quick Release clamp for easy assembly

- High output

- Available in stainless steel M.S., SS304, SS316 & 316L.

- Energy efficient

- Met Polish / Paint Coating

Download Brochure

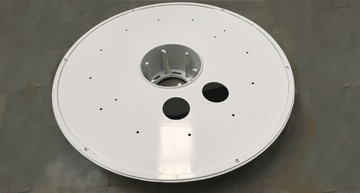

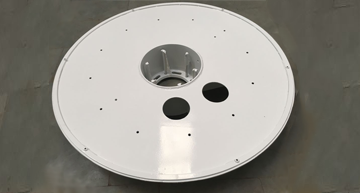

Machine Configuration

| Models | SV-18 | SV-24 | SV-30 | SV-36 | SV-40 | SV-48 | SV-60 | SV-72 | SV-84 |

|---|---|---|---|---|---|---|---|---|---|

| Motor HP | 0.25 | 0.5 | 0.5 | 0.5 | 0.1 | 1.5 | 2.0 | 3.0 | 5.0 |

| Electrical Supply | 3 phase supply / 440V / 50Hz / 1440RPM | ||||||||

| Machine Height | 560mm | 750mm | 895mm | 895mm | 1145mm | 1189mm | 1214mm | 1223mm | 1252mm |

| Wire Mesh Range | 1# (10mm) to 500#(25micron) | ||||||||

Main Products

Navigation

Contact Us

Socialise with us

Contact us via social networks

Copyright © 2018 JS Vibro