Rugged Sieving & Blending Solutions for Stone Powder Processing – Built by JS Vibro

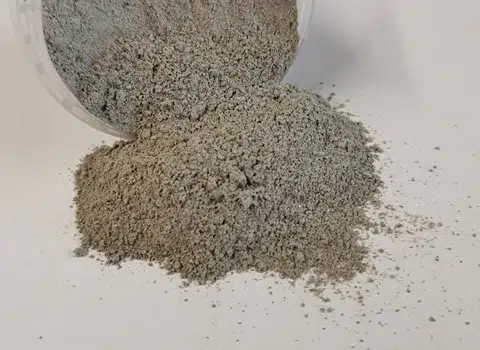

Stone powder—derived from grinding limestone, granite, marble, or basalt—is used in a wide range of industries including construction, ceramics, paint, wall putty, adhesives, and mineral fillers. However, inconsistent particle sizing, contamination, and moisture retention can affect product performance, finish quality, and processing speed.

A leading construction material supplier partnered with JS Vibro to improve their stone powder handling—achieving cleaner batches, consistent mesh sizes, and higher production efficiency.

Purpose-Built Systems for Stone Powder Applications

Vibro Sifter was used to accurately screen stone powder, eliminating oversize particles, clumps, and contaminants—producing a free-flowing, ultra-fine mineral base ideal for use in putties, paints, and filler formulations.

Ribbon Blender enabled uniform mixing of stone powder with adhesives, polymers, pigments, or functional additives—ensuring consistent spreadability, bonding strength, and product quality.

Distinct Advantages of JS Vibro in Stone Powder Processing:

- Heavy-Duty Construction: Handles abrasive minerals like limestone, quartz, and granite

- Fine Mesh Sieving (Up to 300 mesh): Delivers smooth, dust-free powder for coatings and compounds

- Dust-Sealed, Low-Maintenance Design: Improves hygiene and reduces material loss

- Uniform Additive Blending: Supports consistent product performance across batches

- Quick Cleaning System: Ideal for multi-grade or multi-use operations

Perfect For:

- Construction-grade wall putties and tile adhesives

- Paints, primers, and decorative coatings

- Ceramic bodies and glaze preparations

- Polymer and plastic filler compounds

- Cementitious dry mix formulations